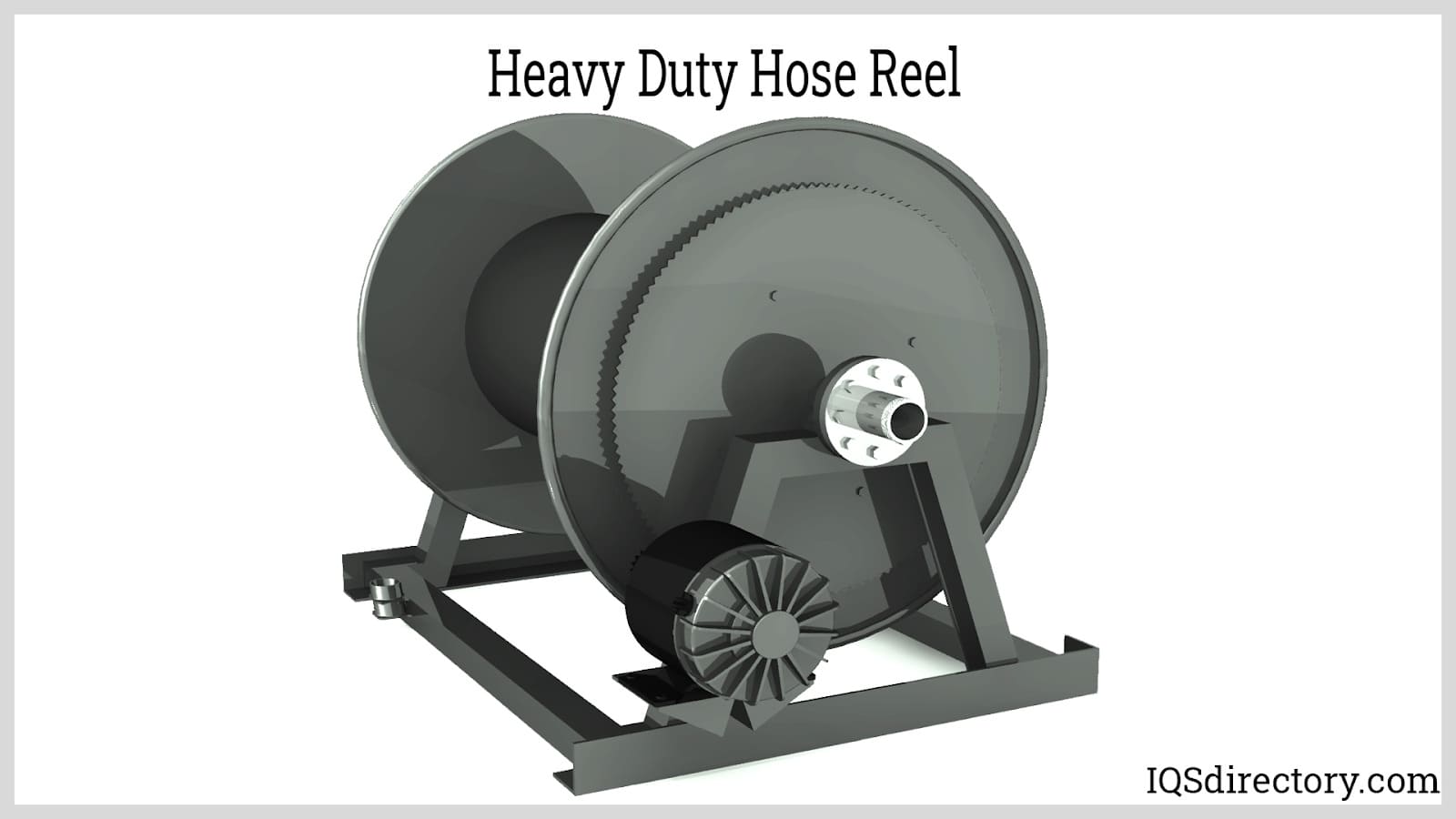

A hose reel refers to a mechanical setup used to properly secure and operate a hose. Heavy duty hose reels are mainly used for hoses that are demanding to use or in applications where the hose is larger than normal. Read More…

Our hose reels are all made in the U.S., with a heavy-duty design and construction, built specifically to fit your needs and never retrofitted to the job.

Unique Hosereels is a global supplier of a variety of hose reels, tank manifold systems and valves. This company can create custom solutions including: electric, hydraulic, manual, air and spring rewind reels from 1" to 4".

Hosetract Industries is a hose reel provider, offering spring hose reels and air hose reels. We provide hose reels designed for industrial and automotive applications as well as many others. Contact us today for your spring hose reel and air hose reel needs — visit our website or call us for details!

Nederman LLC provides high-quality hose reel products and services. Our products are utilized by a variety of industries. Some of those products include hose reels, service reels, cable reels and air hose reels. Please call or visit our website for more information about our products and service.

More Heavy Duty Hose Reel Manufacturers

How Heavy Duty Hose Reels Work

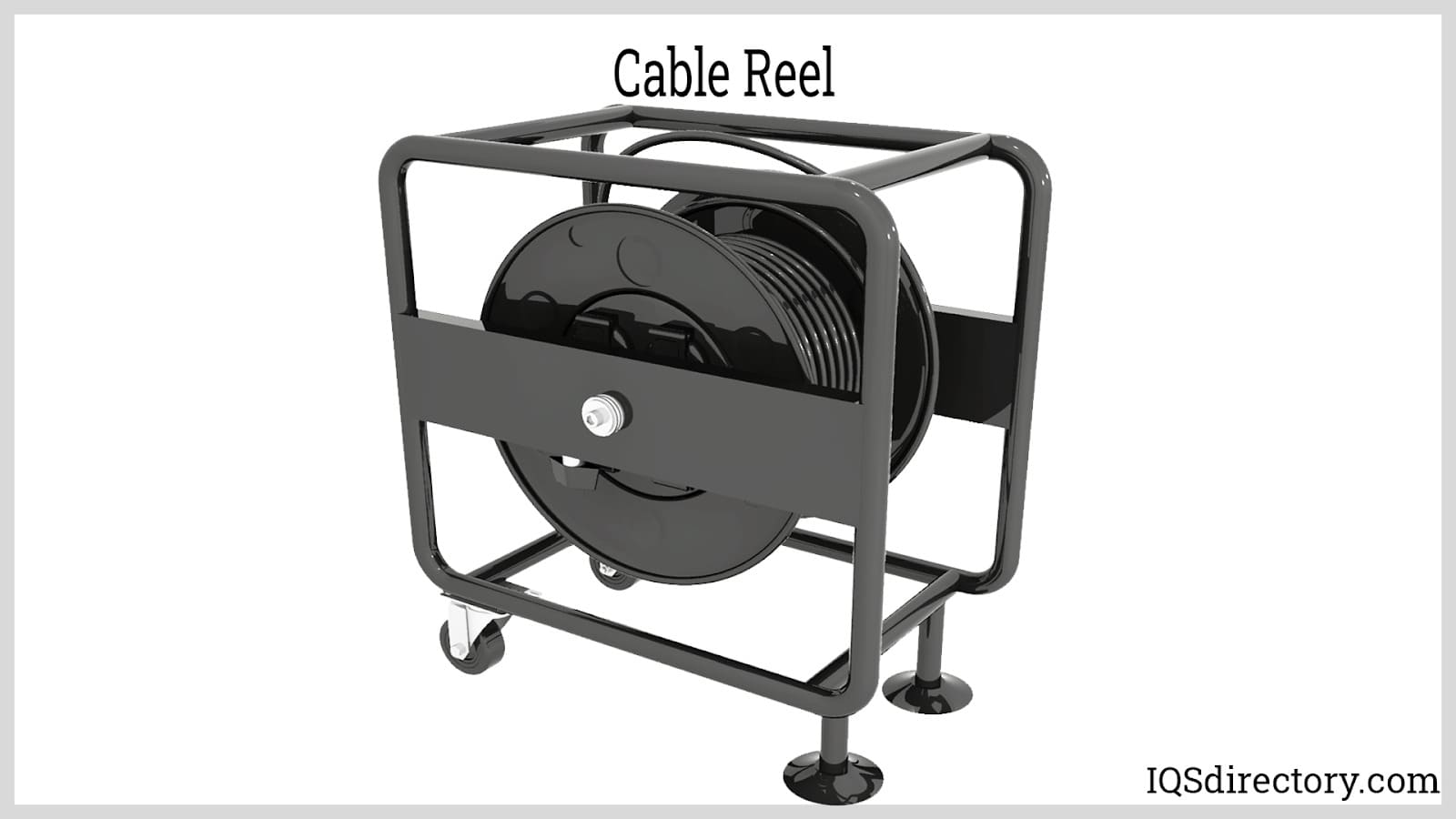

Heavy duty hose reels are usually motor driven. A motor is used as a retraction system to pull back the enormous hose and pack it into the reeling compartment. The motor requires an alternating current (AC) or a direct current (DC) to turn a rotating shaft connected to the reeling system.

The reeling system then winds the hose in the cylindrical compartment where the pipe is neatly packed. Some heavy duty hose reels use pneumatic motors or hydraulic systems to reel in the gigantic horses. Others make use of a manual reeling system that is used to reel in the pipe by hand.

Types of Heavy Duty Hose Reels

There are three main types of heavy duty hose reels: spring-driven reels, hand-cracked reels, and motorized reels. They are commonly used for heavy-duty applications in industries or commercial usage.

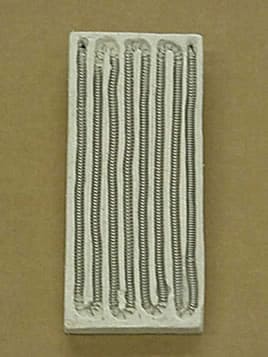

Spring Driven Hose Reels

They are usually referred to as spring rewind reels. They come with a locking ratchet and a paw that permits the user to roll or pull out the packed hose to the desired length and even lock it in that length for ease of use.

Spring-driven hose reels require physically able individuals to pull and use the hope pipe when needed. They do not require an external power source and can be used anywhere but are unsuitable to those who are physically unable to operate the hose.

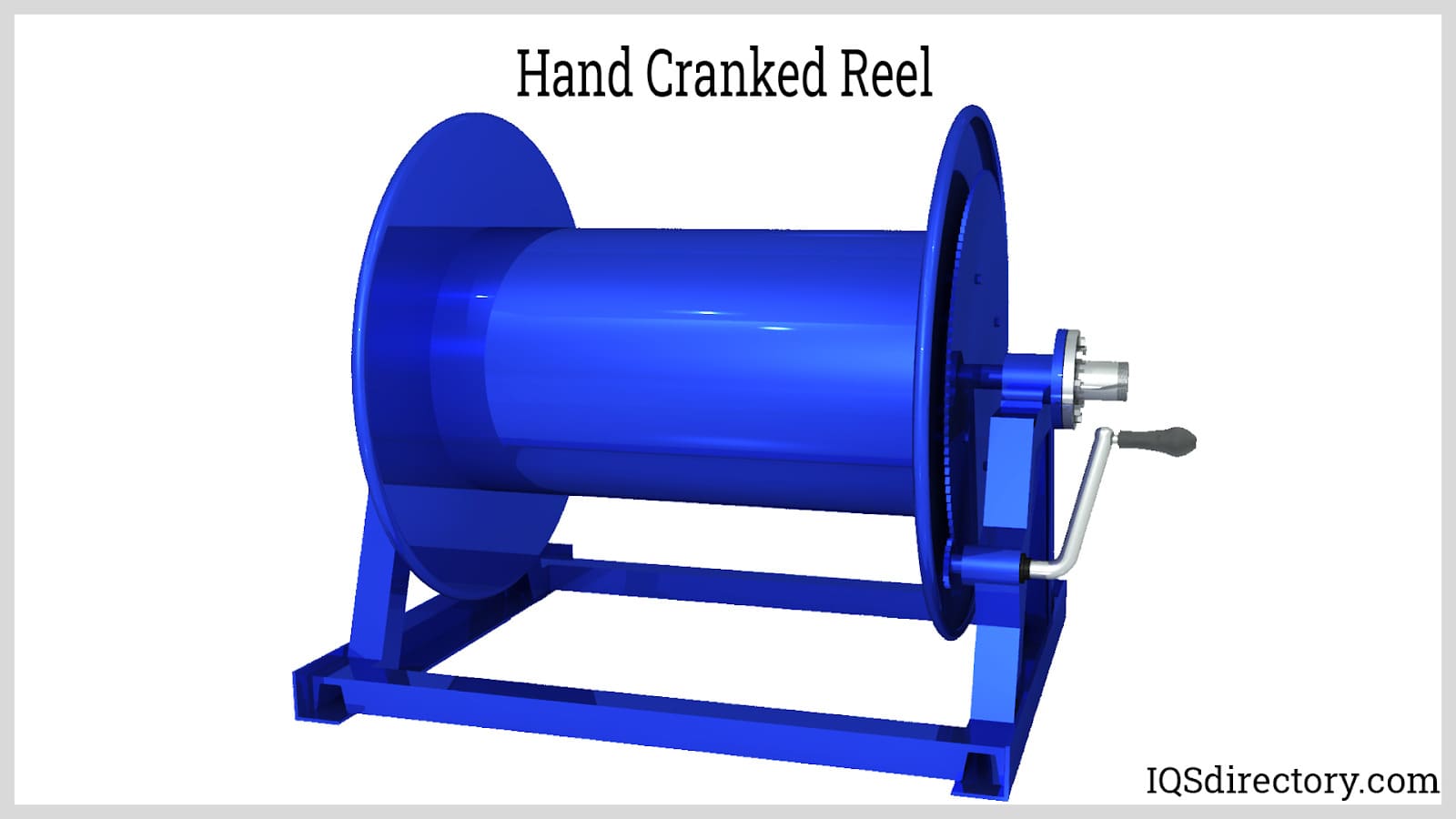

Hand Cranked Hose Reels

Hand-cranked hose reels are also referred to as manual rewind reels. They are commonly used in areas of application where a shorter length of hose is dealt with. It is also a common substitute where there is no external power source. It uses a crank handle connected to the barrel of the reel.

This type is very useful when dealing with a small to medium-sized hose in thickness or length; if the hose becomes any thicker or longer, it will be physically impossible to pull it in or out. Hand-cranked hose reels are the most economical compared to the other two types of heavy duty reels.

Motorized Hose Reels

A motor-driven reel involves a rotating motor attached to the reeling system. The motor uses DC or AC power sources for rotation, and the generated mechanical energy is then used to reel in or out the hose. In most cases, the rotating shaft of the motor has gears that are interlinked to grooves laid out on the hose reel.

The rotating gears, in turn, cause the reel to turn, thus unraveling or winding up the hose pipe. This type of hose reel is very useful as it does not require much physical energy since most of it is generated by the motor. The motion is limited; therefore, it is less complex and does not use up much electrical energy.

Applications and Benefits of Heavy Duty Hose Reels

The applications and benefits of heavy duty hose reels include:

Applications of Heavy Duty Hose Reels

Heavy duty reels are made use of in applications like firefighting equipment. Hoses that spray water on fires are safely wound on heavy duty reels. The reels can then be mounted on vehicles or built onto walls for immediate use in the case of emergencies.

They are also used in hydraulic or pneumatic power tools, portable water or chemicals transfers, and pressurized air or fuel handling.

Advantages of Heavy Duty Reels

Heavy duty hose reels have an impressive storage benefit. The retraction mechanism saves time and effort for users. In addition, a properly stored hose is free from damage and leakages. The reels also improve hose handling.

Choosing the Proper Heavy-Duty Hose Reel Supplier

To ensure you have the most beneficial outcome when purchasing a heavy-duty hose reel from a heavy-duty hose reel supplier, it is important to compare several companies using our directory of heavy-duty hose reel suppliers. Each heavy-duty hose reel supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each heavy-duty hose reel business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple heavy-duty hose reel companies with the same form.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches