Hose reels are cylindrical devices made to house a hose, keeping it kink-free and neat, when it is not in use, by winding the hose around it. A helpful comparison is to think of them as giant spools. Read More…

Our hose reels are all made in the U.S., with a heavy-duty design and construction, built specifically to fit your needs and never retrofitted to the job.

Hosetract Industries is a hose reel provider, offering spring hose reels and air hose reels. We provide hose reels designed for industrial and automotive applications as well as many others. Contact us today for your spring hose reel and air hose reel needs — visit our website or call us for details!

Nederman LLC provides high-quality hose reel products and services. Our products are utilized by a variety of industries. Some of those products include hose reels, service reels, cable reels and air hose reels. Please call or visit our website for more information about our products and service.

When it comes to high quality products, we are driven to provide only the most technologically advanced products available to you. We produce durable hose reels that make your hoses more productive, as well as keeping them easily accessible and longer lasting. Our website features technical support that not only includes service manuals, but tech bulletins and CAD drawings as well. Can’t find...

More Hose Reel Manufacturers

Manufacturers design hose reels to protect hoses and cables from damage and keep them organized, off the ground, unkinked, and safely out of the way when not in use. Hose reels are utilized across various industries, including construction, healthcare, industrial lighting, manufacturing, aviation, welding, and gardening.

The History of Hose Reels

In the 17th century, the Netherlands introduced the first hose reels, created to solve the problem of transporting the newly perfected but heavy fire hoses. Initially designed as drums for easier transport, these reels soon became part of fire truck designs. This effective solution led to the drum wheel’s broader adoption for various purposes.

With the Industrial Revolution came new technologies and materials, allowing manufacturers to produce lighter and more portable fire hose reels. These innovations transformed the original drum design into the spool-like storage mechanisms we recognize today. Over the ensuing centuries, continued advancements in manufacturing and materials further expanded the hose reel industry. Nowadays, hose reels are available in a wide range of sizes, materials, and designs, suitable for diverse applications.

Hose Reel Design

When constructing a hose reel, manufacturers ensure it possesses a robust yet slim core, featuring barriers on each end to secure its contents when wrapped around it. These barriers are essential for maintaining the reel’s integrity and preventing any unwarranted unraveling. Typically, hose reels are hermetically sealed to safeguard against dirt and extraneous moisture, ensuring the durability and longevity of the contents.

Beyond these fundamental characteristics, the construction and design of hose reels are tailored to specific application requirements. Depending on consumer needs, manufacturers make critical decisions regarding various aspects, such as the power source or retractability, the choice of construction materials, the diameter of the hose reel, and its mounting orientation. These considerations ensure that the final product meets the diverse and specific demands of its intended use, providing optimal functionality and reliability.

Hose reels come in manual or mechanical forms. Manual hose reels require users to hand crank the hose back into place, lacking automatic retraction. Mechanical hose reels, except for spring reels, include a motor-powered retraction device, that automatically pulls the hose back. These are sometimes referred to as retraction or electric reels.

Note: Regardless of the retraction type, all hose reels typically feature a latching mechanism to secure the hose at any point during retraction.

Determining the appropriate construction material hinges on the application’s specific needs. Hose reel manufacturers consider attributes such as corrosion resistance, durability, tensile strength, temperature resistance, impact resistance, and non-abrasiveness when selecting materials. For instance, medical cord reels are usually crafted from sanitary-grade materials like 304L stainless steel. In contrast, industrial hose reels require construction from corrosion-resistant, heavy-duty metals, such as certain grades of steel, stainless steel, or aluminum. Typically, reels can be made from plastic, wood, fiberglass, or metals like heavy-gauge steel, stainless steel, and aluminum. Although manufacturers do not fabricate plastic or steel themselves, they maintain open lines of communication with metal fabricators to accommodate requests for custom materials.

Hose reels vary significantly in size, from very small to very large. Garden hose reels are typically smaller than those used in industrial applications, such as fire departments, due to the thinner and lighter nature of garden hoses. Conversely, suction hose reels are often quite wide. In terms of positioning, hose reels can be placed on the ground, over a spigot, on a cart or truck, or mounted on a wall.

Manufacturers offer various customization options for hose reel assemblies. They can apply liquid or powder paint for custom colors. To enhance properties such as corrosion resistance, they can add a strong powder finish to the surface. Additionally, manufacturers can engrave the reel surface or replace handles and hand cranks.

Types of Hose Reels

Manual Hose Reel

Manual hose reels function through the use of a side-mounted handle, which allows for straightforward and efficient retraction and deployment of the hose. These reels are ideal for settings where controlled, hands-on operation is preferred.

Mechanical Hose Reel

Mechanical hose reels, often referred to as automatic hose reels, offer a more advanced solution for hose management. These reels can be powered by electricity, springs, or pneumatics, providing versatility and ease of use in various applications.

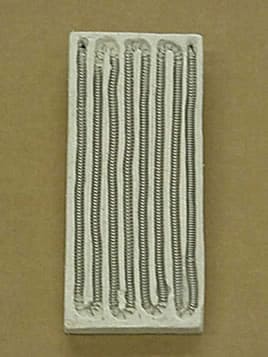

Spring-Powered Hose Reel

Spring-powered hose reels, a subtype of mechanical hose reels, utilize an internal spring mechanism to retract the hose. These reels can also feature self-latching capabilities, enabling the user to initiate the retraction process with the simple flip of a switch or push of a button, thus enhancing convenience and efficiency.

High Pressure Hose Reel

High pressure hose reels are engineered to accommodate pressurized air, water, and other heavy liquids, making them essential for manufacturing and industrial processes. These reels are built to withstand the demands of high-pressure environments, ensuring reliable and efficient fluid management.

Fire Department Hose Reel

Fire department hose reels are specifically designed to support the extra weight and length of firehose tubing, making them robust and durable. Constructed from highly rigid materials, these reels provide easy access to a substantial water supply, delivering over nine liters of firefighting power. They are crucial in high-risk spaces such as theaters, schools, factories, warehouses, concert halls, and hotels, ensuring that firefighters can respond effectively to emergencies.

Medical Cord Reel

Medical cord reels are vital for storing, releasing, and automatically rewinding conductive or lifting cords. These reels facilitate the connection between mobile medical machinery, such as crash carts, and stationary power sources. By ensuring a continuous power supply, they play a crucial role in the seamless operation of medical equipment in healthcare settings.

Exhaust Hose Reel

Exhaust hose reels are essential for managing vehicle exhaust hoses when they are not in use, particularly at work sites. These reels provide an organized and efficient storage solution, ensuring that hoses are readily accessible while maintaining a clutter-free environment. They are typically available with either spring-powered or motorized retractors, catering to different needs and preferences in various work settings.

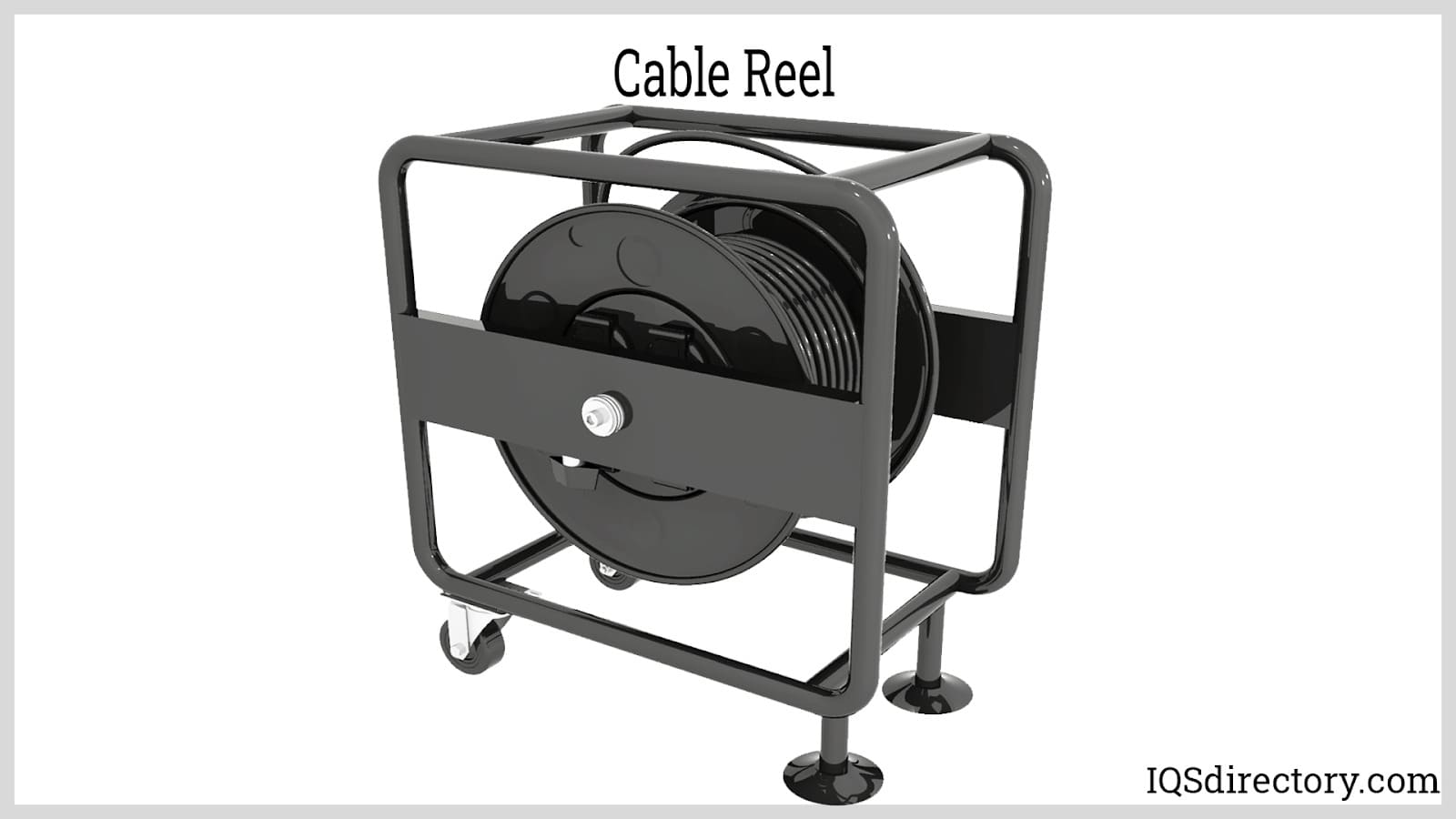

Cable Reel

Cable reels play a crucial role in the storage, winding, and unwinding of various types of electrical cables. Predominantly found in manufacturing facilities and warehouses, these reels are also commonly seen along roadways. They are integral to the smooth operation of systems such as stage sets, aerial work platforms, robotic welding cells, conveyor systems, overhead cranes, rotary equipment, forklifts, hoists, light towers, garage doors, and material handling systems.

There are several types of cable reels, each designed for specific applications. Plywood reels, which are cost-effective, are suitable for lighter loads. Heavy-duty steel reels, known for their recyclability, are ideal for both heavy and large loads. Collapsible cable reels can fold flat for convenient storage. Live connection cable reels allow cables to transmit power while remaining attached to the reel. Reel and cable assembly reels include systems with reels, wires, and other miscellaneous accessories. Lastly, storage cable reels are designed to remain stationary unless the cable is unwound.

Water Hose Reel

Water hose reels are cylindrical devices designed to store and manage hoses that transport water. Depending on application needs, these reels can be either portable or fixed. They are generally categorized by their retraction method, pressure rating (measured in psi), and the length and diameter of the hose they hold. Water hose reels are versatile, serving various applications such as lawn watering, landscaping, industrial cleaning, pressure washing, and water transportation for parks, farms, golf courses, and orchards.

Air Hose Reel

Air hose reels, also known as pneumatic hose reels, are designed to store and manage air hoses for conveying air or harnessing pneumatic power. They are commonly used to transport pneumatic power over long distances when the source is immovable. In stationary applications, air hose reels serve to store the hose when not in use. These reels are widely used in construction, manufacturing, automotive engineering and maintenance, as well as DIY projects.

Extension Reel

Extension reels are essential tools designed to manually or mechanically wind and unwind electrical cords, ensuring they remain tangle-free, organized, and easily accessible. These reels can be mounted on a wall near an outlet or designed for portability, catering to various needs. Their versatility makes them indispensable in numerous environments, including factories, manufacturing facilities, homes, garages, gardens, workshops, and offices. By maintaining order and accessibility, extension reels enhance efficiency and safety in any setting where electrical cords are used.

Cable Carrier

Cable carriers are specialized reels composed of a series of flexible links that effectively store and organize conduits such as hoses, chains, and cables. These innovative devices ensure that various types of conduits remain neatly arranged and easily manageable, preventing tangles and facilitating smooth operations in diverse applications.

Static Discharge Reel

Static discharge reels play a crucial role in maintaining safety by eliminating static electricity buildup. When properly grounded, these reels effectively dissipate any static electricity accumulated by the equipment they wind. This function is vital in preventing potential hazards, ensuring that ground equipment remains safe and operational.

Advantages of Hose Reels

Hose reels offer numerous advantages to their users, primarily through the proper storage and care they provide. By keeping hoses organized and protected, hose reels significantly extend the lifespan of the hoses. They prevent accidental tearing and shield the hoses from damaging elements such as snow and sun. Prolonged exposure to harsh weather conditions can lead to hoses drying out or cracking, but hose reels mitigate these risks effectively.

Moreover, hose reels enhance safety by eliminating the hazards posed by unstowed hoses. A hose left on the ground can be a tripping or falling danger, but when neatly stored on a reel, these risks are substantially reduced. This aspect is particularly important in environments where safety is a priority.

In addition to these safety and durability benefits, hose reels also improve the efficiency and convenience of hose usage. They make it easier to manage hoses, ensuring that they are readily accessible and easy to deploy when needed. This streamlined approach to hose handling enhances the overall productivity of any application, making hose reels an invaluable tool for various settings.

Hose Reel Accessories

Hose reels are essential tools for efficiently storing and managing hoses in various settings, including gardens, workshops, and industrial environments. To enhance the functionality and convenience of your hose reel, consider incorporating a variety of accessories.

O-rings are small rubber rings that serve as seals to prevent water leakage at the hose reel’s connection points. These rings can wear out or become damaged over time, so having replacements on hand is crucial for maintaining a watertight seal and ensuring optimal performance.

Wall Mount Brackets are designed to securely attach hose reels to walls or other vertical surfaces. They provide stability and keep the hose reel off the ground, thereby saving space and making it easier to access and use the hose. This is particularly useful in areas where space is limited.

Reel Carts are wheeled frames that hold hose reels, allowing for easy mobility around large areas. They are ideal for gardens or industrial settings where the hose needs to be moved frequently. With reel carts, transporting hoses becomes more efficient, reducing the effort required to cover extensive spaces.

Ball Stops are essential devices placed at the end of the hose on the reel. Their primary function is to prevent the hose from completely retracting into the reel, keeping the end of the hose accessible. This feature ensures that the hose is always ready for use, enhancing convenience and efficiency.

Drills are vital tools when mounting the reel to a wall or other surfaces. They are used to create holes necessary for securing the wall mount brackets or reel cart. Ensuring the reel is firmly attached is crucial for its stability and reliable operation, particularly in high-traffic or industrial settings.

Air Guns, also known as air blow guns, are attachments that can be added to the end of the hose to blow compressed air. These tools are particularly useful for cleaning or drying applications. By directing a powerful stream of air, air guns can efficiently remove debris or moisture, making them invaluable in workshops and industrial environments.

Speed Controls are crucial for regulating the rewinding speed of the hose onto the reel. This feature ensures a controlled and smooth hose retrieval process, minimizing the risk of accidents and extending the hose’s lifespan. By preventing abrupt retractions, speed controls help maintain the hose’s integrity and functionality.

Cable/Cord/Hose Bumpers are protective accessories designed to prevent damage during the winding and unwinding process. These bumpers are strategically placed around the hose reel to safeguard both the hose and surrounding objects. Their presence reduces wear and tear on the hose and minimizes the risk of impact damage to nearby items, enhancing the overall durability and safety of the hose reel setup.

Hose Assemblies offer a convenient solution for hose reel users. These pre-assembled hoses come with the correct length and connections, ready to be attached directly to the reel. By eliminating the need for manual assembly, hose assemblies save time and effort, ensuring a seamless and efficient setup. This not only simplifies the installation process but also guarantees optimal performance and reliability.

Rewind Motors are a valuable feature in some hose reels, automating the rewinding process. This automation significantly reduces the need for manual labor, making it much easier to handle longer or heavier hoses. With rewind motors, the task of retracting the hose becomes effortless, enhancing efficiency and convenience, particularly in demanding environments.

Roller Guide Assemblies are another essential component, especially for larger hose reels. These assemblies guide the hose smoothly onto the reel during the rewinding process, preventing tangling and ensuring even distribution. By maintaining an organized and tangle-free hose, roller guides enhance the longevity of the hose and improve the overall functionality of the reel system.

To identify the necessary accessories for a hose reel, start by evaluating the specific application and requirements. In stationary garden environments, you may require wall mount brackets and O-rings. For greater mobility needs, a reel cart might be advantageous. In industrial settings where flexibility and control are crucial, consider incorporating air guns and speed controls.

These accessories are available from a variety of sources, including specialized hardware stores, garden centers, online retailers, and industrial equipment suppliers. Many manufacturers also provide accessory kits that are tailored to their hose reel models, so it’s important to verify compatibility with your specific model.

Choosing the right accessories can greatly enhance the efficiency, convenience, and durability of your hose reel system. By assessing the particular needs of your application, you can determine which accessories are necessary and source them from the appropriate retailers.

Hose Reel Installation

The complexity of hose reel installation varies depending on the type of reel. For wall-mounted hose reels, carefully follow the manufacturer’s instructions and ensure you have the appropriate screws and nails. Do not substitute recommended fasteners with tape or glue, regardless of their strength. For portable hose reels, the installation process is simpler. However, ensure the reel is securely positioned and that its weight is evenly distributed to prevent tipping.

Proper Care for Hose Reels

To ensure the longevity and continued effectiveness of your hose reel, proper storage is essential. First and foremost, it is crucial to keep your hose reel in a cool and dry environment. This is especially important if the reel is constructed from materials prone to corrosion or rust. Additionally, the reel should be placed in a designated storage area, away from high-traffic zones within the workplace, to prevent accidental damage.

When the hose is not in use, it is imperative to wind it back onto the reel. Neglecting this practice can lead to unnecessary wear and tear, potentially reducing the lifespan of the reel. Lastly, if your hose reel features advanced settings, ensure these settings are accurately configured before activating the system to avoid any operational issues.

Hose Reel Standards

The standards for hose reels depend on their application, industry, and regional or national regulations. For example, fire hose reels are subject to specific standards that vary by country, with the National Fire Protection Association setting the criteria in the United States. Hose reels used for compressed air must comply with safety standards established by OSHA. Globally, various organizations set additional safety and performance standards, including the International Standards Organization (ISO), British Standards Institute (BSI), Conformité Européenne (CE), European Standards (EN), and Australian Standards (AS).

Things to Consider About Hose Reels

When considering the purchase of a hose reel, several key factors should guide your decision. First, evaluate the type of medium conveyed through your hose, as this will determine the necessary torque and inner diameter of the reel, as well as the appropriate material for its construction. Additionally, the length and weight of the hose are critical, as they influence the choice of material for the latching mechanism.

If a hermetically sealed reel is required, opt for a spring hose reel to ensure proper sealing. Equally important is the selection of a manufacturer. Choose a supplier who is not only reliable and cost-effective but also excels in customer service. The overall performance of your hose reel is closely tied to the support provided by the manufacturer, making high-quality customer service essential for achieving the best results. To identify reputable manufacturers or suppliers, refer to the recommended partners listed on this page. All of our partners are proven providers with a track record of excellence.

Check out our Power Cords website

Check out our Brushes website

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches